SINAMICS G150 NEMA

Type A enclosed drive

2

Siemens D11.7

(Part 1) – 2013

2/10

2/10

Description of options

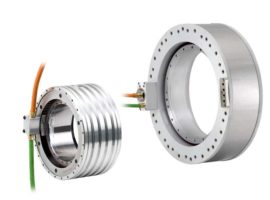

K50

SMC30 sensor module for speed feedback

The SMC30 encoder module is used to connect a speed

feedback encoder to the drive. Rotary pulse encoder signals

are converted for evaluation via the DRIVE-CLiQ interface of

the controller.

The following encoders are supported by the SMC30:

• TTL encoders

• HTL encoders

The motor temperature can also be detected using a

KTY84-130 sensor or PTC thermistors. Refer to engineering

information for details.

K51

VSM10 voltage sensing module

The VSM10 Voltage Sensing Module reads the voltage

waveform at the drive output. This provides the flying restart

function when the SINAMICS G150 drive is connected to a

permanent magnet synchronous machine without encoder.

The VSM10 is wired to the motor terminals with short-

circuit-proof wiring.

K52

Additional SMC30 Sensor Module

This option code is to add a second SMC30 sensor module

(in addition to one specified by option K50). Two SMC30 with

associated encoders are required for Safety Extended functions.

K82

Terminal interface for controlling the “Safe Torque Off”

and “Safe Stop 1” safety functions

This terminal interface offers a wide voltage range (24 V to

240 V DC or AC) for easy integration of the following basic

Safety Integrated functions into the plant controls:

• Safe Torque Off (STO)

• Safe Stop 1 (SS1) (time-controlled)

The components inside the drive (Control Unit and Power

Module, from the terminals on these devices) are certified

in combination with firmware versions to satisfy the

requirements of the following standards. With option K82

the enclosed drive unit also meets the requirements of:

• Machinery Directive 98/37/EC

• IEC 60204-1

• ISO 13849-1 Category 3, for Performance Level (PL) d

• IEC 61508 SIL 2

These Safety Integrated functions of SINAMICS G150 are

generally certified by independent institutes. An up-to-date

list of certificates is available on request from your local

Siemens office.

K87

TM54F Terminal Module

The TM54F Terminal Module provides fail safe digital inputs

and outputs for hardwired control of the Safety Integrated

extended functions (as opposed to control via bus

communications with PROFIsafe).

Safety Integrated extended functions require a safety license

(option

K01

).

The TM54F must be connected directly to the Control Unit

via DRIVE-CLiQ.

Note: It is not permissible to connect the Power Module to a

TM54F. The TM54F has 4 fail safe digital outputs and 10 fail

safe digital inputs. A fail-safe digital output consists of one

24 V DC switching output, an output switching to ground

and one digital input to check the switching state. A fail-safe

digital input consists of two digital inputs.

K88

Safe Brake Adapter SBA, 230 V AC

Safe Brake Control (SBC) is a basic safety function that is

used in safety-relevant applications, for example in presses

or rolling mills. In the no-current state, the brake is applied

to the drive motor shaft using spring force. The brake is

released when current flows in it (low active).

The Safe Brake Adapter 230 V AC is factory installed in the

开车。电源连接到终端-X12 on

the Safe Brake Adapter. For control, a connection is

established between the Safe Brake Adapter and the Control

Interface Module in the factory using a wire harness.

On the plant side, to control the brake, a connection must be

made between terminal -X14 on the Safe Brake Adapter and

the brake.

Note: The safe brake adapter is not yet UL listed. Option

K88 cannot be included in a UL listed drive.

K95

CU320-2 PN Control Unit

Replace the standard CU320-2 DP with PROFIBUS port by the

CU320-2 PN with PROFINET port

L08

Motor reactor

Motor reactors reduce the voltage load on the motor windings

by reducing the voltage gradients (dV/dt) generated by the

drive at the motor terminals. (Note that a motor reactor does

not increase the maximum motor cable length for SINAMICS

G150 – refer to engineering information).

L10

Output dV/dt-Filter with VPL (Voltage Peak Limiter)

加上VPL的dV / dt过滤器llows the connection of non-

inverter duty motors to the SINAMICS G150 drive.

For motors insulated per NEMA MG1, part 30 (voltage peaks

<1,000 V and dV/dt <500 V/µs) the maximum allowable

motor cable length is as follows. Note that longer cable

lengths of up to 450 m are possible, but voltage peaks may

exceed 1,000 V. Please refer to engineering information for

additional details.

Rated voltage

Maximum motor cable length

for motors insulated per NEMA MG1, part 30

Unshielded cable

Shielded cable

380 – 480 V

980’ (300 m)

980’ (300 m)

500 – 600 V

490’ (150 m)

490’ (150 m)