2/2

Siemens D 83.1 · 2016

2

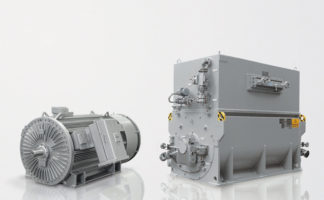

Motors with Explosion Protection

Orientation

■

Overview

In many industrial and public sectors, explosion protection or

explosion hazards are ever-present, e.g. in the chemicals

industry, in refineries, on drilling platforms, at gas stations,

in feed manufacturing and in sewage treatment plants.

The risk of explosion is always present when gases, fumes,

雾或dust are mixed with oxygen in the air in an explosive ratio

close to sources of ignition that are able to release the so-called

minimum ignition energy.

In the chemical and petrochemical industries in particular, when

crude oil and natural gas are transported, or in mining, milling

(e.g. grain and granular solids), this can result in serious injury

to persons and damage to equipment.

To ensure maximum safety in these areas, legislators in most

countries have implemented appropriate stipulations in the form

of laws and regulations based on national and international

standards.

Explosion-protected equipment is designed such that an

explosion can be prevented when it is used properly.

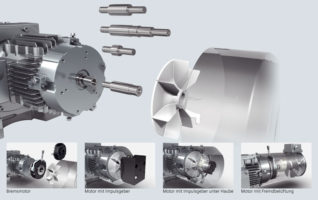

The explosion-protected equipment can be designed in

根据各种类型的保护。

The local conditions must be subdivided into specified zones

by the user with the assistance of the responsible authorities in

accordance with the frequency of occurrence of an explosion

hazard. Device (equipment) categories are assigned to these

zones. The zones are then subdivided into possible types of

protection and therefore into possible equipment (product)

types.

分类区

Areas subject to explosion hazard are divided into zones.

Division into zones depends on the chronological and

geographical probability of the presence of a hazardous,

potentially explosive atmosphere. Information and specifications

for classification of the zones are laid down in the following

standards:

•

IEC/EN 60079-10-1 for gas atmospheres

•

IEC/EN 60079-10-2 for dust atmospheres

Further, a distinction is made between various explosion groups

as well as temperature classes and these are included in the

hazard assessment.

Depending on the particular zone and therefore the associated

hazard, operating equipment must comply with defined

minimum requirements regarding the type of protection. The

different types of protection require corresponding measures to

prevent ignition that should be implemented at the motor in order

to prevent that a surrounding explosive atmosphere is ignited.

Zone classification

Gas atmosphere

Zone classification

Dust atmosphere

Zone 22

Zone 21

Zone 0

Zone 1

Zone 2

Zone 20

Safe Area

Safe Area

G_D081_EN_00339

Zone

Zone definition acc. to

Gas

1) 2)

Dust

1) 2)

IEC/EN 60079-10-1 for gas atmospheres

IEC/EN 60079-10-2 for dust atmospheres

Assigned

types of protection

Category

according to

2014/34/EU

Equipment protection

level acc. to

IEC/EN 60079-0

0

–

An area in which there is an explosive gas atmosphere

constantly

,

over a long period

or

frequently

.

Low-voltage motors

not permitted

1

Ga

1

–

An area in which in normal operation it is expected that an explosive gas

atmosphere will occur

occasionally

during normal operation.

Ex e

Ex de

Ex d

2

Gb

2

–

An area in which in normal operation it is expected that an explosive

gas atmosphere will occur only

rarely

and then only

briefly

.

nA交货

3

Gc

–

20

An area in which there is an explosive gas atmosphere comprising

a dust-air mixture

constantly

,

over a long period

or

frequently

.

Low-voltage motors

not permitted

1

Da

–

21

An area in which it is expected that an explosive gas atmosphere comprising

a dust-air mixture will occur

occasionally

during normal operation.

Ex tb

2

Db

–

22

An area in which in normal operation it is expected that an explosive gas

atmosphere in the form of a cloud of flammable dust in air will occur only

rarely

and then only

briefly

.

Ex tc

3)

3

Dc

1)

Motors of

- Zone 1 may also be used in Zone 2.

- Zone 21 may also be used in Zone 22.

2)

Motors which are certified for gas or dust protection must not be used in

hybrid mixtures! Hybrid mixtures:

When explosive gas and dust atmospheres occur simultaneously.

3)

Motors are not approved for operation in environments containing

conductive dust.

© Siemens AG 2016