FLENDER Standard Couplings

Taper Clamping Bushes

14/3

Siemens MD 10.1 · 2015

General information

14

■

Design

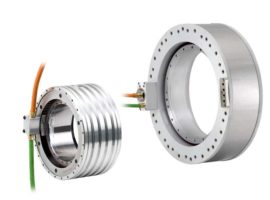

Taper clamping bushes are designed with a cylindrical bore and

a parallel keyway. A Taper clamping bush has a tapered outside

diameter and fits into the taper bore of the hub part. The Taper

clamping bush has a slot running along its length. To fit, half

blind holes are drilled in the Taper clamping bush, while on the

opposite side half thread turns are cut in the hub part. With the

aid of the fitting bolts, which are supported on the base of the

blind holes, the Taper clamping bush is pushed into the taper

bore. The Taper clamping bush is compressed, thus generating

a parallel key and clamp connection between shaft and hub

part.

To dismantle, the fitting bolts are removed and screwed into the

forcing-off threads. The forcing-off threads are cut half in the Ta-

per clamping bush and half in a blind hole in the hub part. When

the forcing-off bolts are fitted, the Taper clamping bush is forced

out of the taper hub bore. The connection is broken.

The Taper clamping bush and the fitting and dismantling bolts

are always screwed in from the larger outer diameter side of the

taper.

The torque is transmitted via the clamping connection and the

平行键。没有轴向固定ture is required with normal axial forces,

as the clamping connection is sufficient.

Materials

Grey cast iron EN-GJL-220 to 250

alternatively: Steel

© Siemens AG 2015