FLENDER Standard Couplings

Highly Flexible Couplings — ELPEX-S Series

General information

11/2

Siemens MD 10.1 · 2015

11

■

Overview

Coupling suitable for use in potentially explosive

atmospheres.

Complies with the current ATEX Directive for:

II 2 G T3 D160 °C X

II 2 G T4 D120 °C X

(Type EST is not available in Ex version.)

ELPEX-S couplings are highly torsionally flexible and because of

their low torsional stiffness and damping capacity are especially

suitable for coupling machines with a highly non uniform torque

pattern.

标准ELPEX-S coupling types are designed as flange-shaft-

connections or shaft-shaft connections. Application-related

types can be implemented on request.

■

Benefits

The ELPEX-S coupling is suitable for horizontal and vertical

mounting positions or mounting at any required angle. The cou-

pling parts can be arranged as required on the shafts to be con-

nected.

ELPEX-S couplings are especially suitable for reversing opera-

tion or operation with changing directions of load.

The rubber disk elements are fitted virtually without backlash

and give the coupling linear torsional stiffness, i.e. the torsion

stiffness remains constant even when the load on the coupling

increases.

There are 4 different rubber element versions with different

grades of torsional stiffness available for each size from stock.

On certain types the flexible rings can be changed without hav-

ing to move the coupled machines.

如果大量超载occurs, the rubber disk element of the

coupling is irreparably damaged, the coupling throws the load

and thus limits the overload for particular operating conditions.

The coupling can be inserted and fitted blind e.g. in a bell hous-

ing.

There are outer flanges with different connection dimensions

available for each coupling size.

■

Application

The ELPEX-S coupling is available as a catalog standard in 12

sizes with rated torques of between 330 Nm and 63000 Nm.

The coupling is suitable for ambient temperatures of between

-40 °C and +120 °C.

The ELPEX-S coupling is frequently used for diesel motor drives

或往复式压缩机驱动器。因为迪fferent rub-

ber versions enable the torsional stiffness to be adjusted to meet

requirements, the coupling is also suitable for drives which re-

quire a specific and preferably precalculated torsional vibration

behavior setting.

■

Design

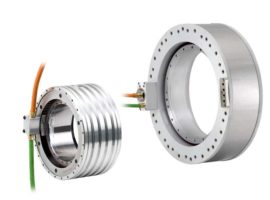

The rubber disk element is vulcanized onto a flange on the in-

side diameter. The flange can mount e.g. a Taper clamping bush

or a hub. On its outer diameter the rubber disk element has driv-

ing teeth, which are inserted into the outer flange. The torque is

transmitted positively between the rubber disk element and the

outer flange.

In the type for shaft-shaft connection the outer flange is screwed

to a flange hub mounted on a machine shaft.

Materials

Elastomer materials of the rubber disk element

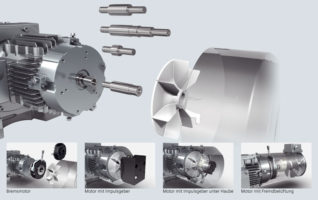

ELPEX-S coupling types

Type EST

Types ESN. and ESD.

Rubber disk element

Grey cast iron

EN-GJL-250/elastomer

Spheroidal graphite

cast iron

EN-GJL-400/elastomer

Hubs, part 1, part 2

Steel

Steel

Outer flange

Cast aluminum

AlZnSi108..

Sizes 680 and 770

of spheroidal graphite

cast iron

EN-GJS-500

Cast aluminum

AlZnSi108..

Sizes 680 and 770

of spheroidal graphite

cast iron

EN-GJS-500

Material / description

Hardness

ShoreA

Iden-

tifica-

tion

Ambient

temperature

Natural-synthetic rubber mixture

50 ° … 55 ° WN

-40 °C … +80 °C

Natural-synthetic rubber mixture

60 ° … 65 ° NN

-40 °C … +80 °C

Natural-synthetic rubber mixture

70 ° … 75 ° SN

-40 °C … +80 °C

Silicone rubber

55 ° … 65 ° NX

-40 °C … +120 °C

Type

Description

ESN

Coupling with hub, long or short version

ESD

Coupling with hub, with two rubber disk elements

ESNR

Coupling with hub, rubber disk element radially dismountable

ESDR

Coupling with hub with two rubber disk elements; rubber disk

elements radially dismountable

ESNW

Coupling designed as a shaft-shaft connection with a rubber disk

element; rubber disk element radially dismountable

ESDW

Coupling designed as a shaft-shaft connection with two rubber disk

elements; rubber disk element radially dismountable

EST

Coupling suitable for mounting a Taper clamping bush

© Siemens AG 2015