FLENDER Standard Couplings

Technical Information

2/3

西门子MD 10.1 · 2015

2

Balancing

Because of primary shaping processes and machining, the cou-

pling components are manufactured with a mass distribution

about the axis of rotation of the motor, gear unit or driven ma-

chine which is not always ideal.

平衡意味着改善旋转的质量分布

身体使其在轴承上旋转,足够有限

自由离心力的影响。

不平衡力随着距离而线性增加

tween the center of gravity of the body and the axis of rotation,

身体的重量和转子速度平方。

F = imbalance force

S =身体重心

E =身体重心与枢轴轴的距离

在里面case of rotating unbalanced coupling parts rotary, imbal-

ance forces develop which impose loads on the bearings of the

machine shafts and excite vibration. High vibration values on

如果是初始启动,经常在初始启动时检测到驱动器

balance of the machine shafts or the mounted coupling parts is

在sufficient or the balancing specifications are incompatible. The

耦合的平衡状况可以在Balanc-

在g machines. By adding or drilling away material, a balance

满足要求的条件可以达到。

平衡质量水平

所谓的质量水平G到Din ISO 1940表示范围

of permitted residual imbalance from zero up to an upper limit.

申请can be grouped on the basis of similarity analysis.

对于许多应用,耦合平衡质量g 16是

高高。在驱动器上容易振动的平衡质量

should be G 6.3. Only in special cases is a better balance qual-

需要。

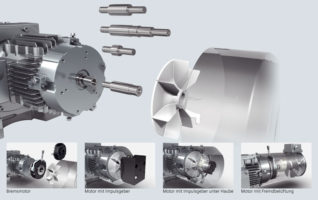

单级和两级平衡

对于盘状体(例如制动盘,耦合轮毂),

called single-level balancing is carried out. The mass compen-

不平衡的原样仅在一个层面上进行。为了

历史原因单层平衡也被称为静态

balancing. On long bodies such as adapters mass compensa-

tion must be implemented at two levels to reduce the couple im-

balance. Two-level balancing is carried out while the rotor body

正在旋转。从历史上看,这被称为动态平衡。

Balancing standard in accordance with DIN ISO 21940-32

Besides the required balance quality, it is necessary to set stan-

定义平行键的质量是如何为

taken into consideration when balancing. In the past, motor ro-

tors have frequently been balanced in accordance with the full

parallel key standard. The "appropriate" balance condition of the

耦合在g hub was described as "balancing with open keyway" or

“在关键后平衡”。今天,电动机转子通常是

以及齿轮单元和驱动的机器轴,将

按照半平行密钥标准的吻合。

Full parallel key standard

平行钥匙插入轴键道,然后平衡

is carried out. The coupling hub must be balanced without par-

按键后的allel键。用“ F”对轴和轮毂进行标记(用于

“满的”)。

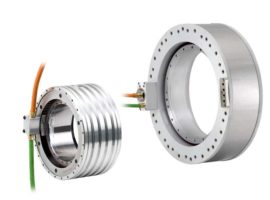

Half parallel key standard

The balancing standard normally applied today. Before balanc-

在g, a half parallel key is inserted in the shaft and another in the

耦合在g hub. Alternatively, balancing can be carried out before

cutting the keyway. The balanced parts must be marked with an

"H". This marking can be dispensed with if it is absolutely clear

which parallel key standard has been applied.

没有平行密钥标准

缩放后的轴和耦合轮毂的平衡,但与 -

平行钥匙。在实践中不使用。轴和轮毂的标记

用“ n”(对于“否”)。

平行钥匙的长度由轴键道确定。

Coupling hubs may be designed considerably shorter than the

shaft. To prevent imbalance forces caused by projecting parallel

按照一半平行的平衡时的关键因素

key standard in the case of applications with high balancing

质量要求,可以安装凹槽的间隔环或

stepped parallel keys used.

西门子平衡标准

平衡质量水平,以及运行速度,

results in the maximum permissible eccentricity of the center of

耦合或耦合子组件的重力。在里面

西门子article number the balancing quality can be preset with

the help of the order code. Additionally, also the balance quality

level to DIN ISO 1940 can be preset together with the operating

属于它的速度,然后将其视为优先级。

The procedure to determine the Siemens balancing quality

is as follows:

已知运行速度和所需的平衡质量水平

从应用程序。使用这些值,所需的偏心

可以使用指定的重力中心的质量计算

公式上下文或以下图。怪异

耦合的重心必须小于所需的

eccentricity of the center of gravity to achieve the required bal-

ANC质量。相关的文章编号必须在

命令;只有选择了标准平衡,

要分配的ticle数

e

耦合

≤

e

珀斯。

允许:

重心的偏心

e

珀斯。

在

μ

m

重心的偏心

of the coupling

e

耦合

在

μ

m

平衡质量水平

G

在mm/s

耦合速度

n

在rpm中

订单代码以确定余额质量级别

dIN ISO 1940 and the operating speed:

Y95 {g = __;n = __rpm}。

<

*B0'43B;;B33339

)

你

d

=

:

H

偏心

gravity of coupling

e

耦合

西门子

平衡质量

Order code

maximum 100

μ

m

standard balancing

没有规格

maximum 40

μ

m

fine balancing

W02

maximum 16

μ

m

micro-balancing

W03

比16更好

μ

m

special balancing

on request

e

perm

9600

G

n

---

⋅

=

© Siemens AG 2015