Automation in production, logistics, and processes – sensor solutions from SICK are the key to digitizing industry.

From factory automation to logistics automation and process automation, SICK’s sensor solutions are keeping industry moving. As a technology and market leader, provides sensor intelligence and application solutions that create the perfect basis for controlling processes securely and efficiently, protecting individuals from accidents, and preventing damage to the environment.

生病的配件

从电气连接器通过反射器和机械安装系统,Sick提供了全面的配件,以保护应用程序解决方案的可用性。这些配件与相应的传感器完美匹配,为成本效益的集成到系统提供了基础,并且可以在短时间内提供。病人甚至能够快速提供特定于客户的开发和修改。

Sick Gas Analyzers

Sick基于各种强大的测量原则提供了广泛的天然气分析仪。借助其现场和提取性测量技术,可为完整的设施提供完整的设施,还可以为各种系统和复杂的测量任务提供解决方案。

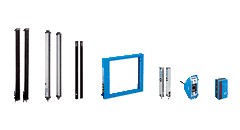

病安全灯窗帘

安全灯窗帘为危险点和危险区域提供可靠且具有成本效益的访问保护。根据变体,集成了不同的机器功能或可以通过安全控制解决方案选择。该范围包括小型和紧凑的设计,以及针对特殊环境条件的极其坚固且具有弹性的变体。

Sick automation light grids

二维检查或计数任务在自动化中很重要。SICK的自动化光网格可用于许多这样的解决方案,例如检测和计算不规则形状的物体,人和车辆,并检查存在和托盘悬垂检测。这些任务是如此的通用,以至于一个光网格无法满足每个应用程序的要求。病假的光网格提供了多个范围,高度,大小,方向和决议,这些范围通过高灵活性和性能简化整合。

Sick safety camera sensors

来自病态的安全摄像头传感器是基于图像处理技术的电敏感保护设备。发件人和接收器已集成到一个外壳中。紧凑型相机传感器不需要任何其他软件,并且可以按按钮进行调试。自动对齐在定义保护区时具有很高的灵活性。机器设计中的高度自由度优化了操作员的人体工程学。

生病的粉尘测量装置

病人正在用坚固且低维护的测量设备来检测和监测灰尘浓度的设备,以确定灰尘测量的新标准。所有的灰尘测量设备都易于集成到现有应用中,并提供直接的安装和调试以及用户友好的操作。

生病的编码器

路径,位置,角度 - 在工业自动化中精确的位置检测时,编码器是理想的解决方案。同样适用于测量旋转和RPM以及速度和加速度。高分辨率的光学编码器和极度坚固的磁编码器互相补充,并允许在各种应用中进行精确测量。旋转编码器可作为增量和绝对编码器提供。线性测量技术可提供带有测量元素的线性编码器和线性编码器。

Sick Safety switches

Safety switches are indispensable in any application where safety is required for people and machinery. They are used for protecting movable physical guards, determining the position of dangerous movements, and the safe stop function. The portfolio is divided into electro-mechanical and non-contact safety switches, safety locking devices, and safety command devices. In conjunction with safe control solutions, SICK offers ideal complete solutions from a single source.

Sick Safety laser scanners

病态的安全激光扫描仪结合了专有技术和最高性能的经验。无论是移动设备还是固定,用于区域保护或访问保护,在室内或室外 - 我们的全面投资组合都为每项要求提供了正确的成本效益包装。使用飞行时间测量原理,紧凑型设备扫描其周围环境和尺寸距离。集成的旋转镜允许客户定义的保护区域在二维中受到监视。

病态整合产品

来自病态的集成产品在现场级别的各种传感器以及传感器数据传输到云中。为了与行业4.0保持一致,数据是直接或以预处理形式提供的,以便运行更高级别的流程,例如预测性维护,跟踪,跟踪和质量控制。

病态安全多台扫描仪

安全多波束扫描从生病的结合nefits of a safety light curtain with the benefits of a safety laser scanner. Thanks to the safe solid state technology of the LiDAR sensors, sender and receiver units without moving parts can be compactly integrated in one device. The result: A new dimension of innovation.

病态感官:控制 - 安全控制解决方案

智能机器设计还专注于提高生产率,还提供了最佳的质量和安全性。SENS:控制 - 生病的安全控制解决方案满足了这些要求。产品组合包括安全系列连接,安全控制器和安全继电器。这些产品以轻松的调试,模块化和与自动化过程的最佳集成给人留下深刻的印象,以使人与机器之间的最佳相互作用。

生病的光纤传感器和纤维

When installation space is extremely limited or the objects to be detected are tiny, fiber-optic sensors are the ideal solution. If it is necessary for even higher requirements to be fulfilled, such as sensing range, temperature resistance, material durability or a flexible mounting process, the intelligent combination of sensors and fiber-optic cables can provide the perfect solution. A wide range of fiber-optic cables with application-specific optical heads ensure that every need is met.

生病的叉传感器

SICK fork sensors combine senders and receivers in a single housing, meaning that they can be adjusted quickly. Thanks to the precise, focused light beam and the high detection accuracy, the sensors also detect very minor light attentuation differences. Many different fork sizes, straightforward mounting, and exceptionally high ambient light immunity are just some of the advantages of these fork sensors.

病阵列传感器

Array sensors operate on the proximity scanning principle. They detect even the smallest edges based on differences in grayscale values within the field-of-view. Positioning of, for example, a paper web based on the web edge or a contrast line is only one of many possible applications. Widths, diameters, and gaps can also be detected. In reflector mode, the array sensors can even detect transparent materials.

病态的颜色传感器

颜色传感器检测表面的颜色。的年代ensors cast light (red, green, and blue LEDs) on the objects to be tested, calculate the chromaticity coordinates from the reflected radiation and compare them with previously stored reference colors. If the color values are within the set tolerance range, a switching output is activated.

Sick Contrast sensors

对比传感器主要用于包装/打印机,用于检测印刷或控制标记。SIX的KT对比度传感器线甚至在最高速度下都检测到最小的对比度,例如箔或包装上的打印标记。他们检测到哑光,闪亮或透明表面的标记和背景之间的微小灰度变化。各种具有不同对比度分辨率方法和教学版本的设备类型可用于满足广泛的要求。

病态的距离传感器

Sick具有各种各样的视频和超声波解决方案,可测量从亚微米到公里。他们使用三角测量和飞行时间模式来解决测量,检测和定位应用。使用三角剖分的传感器非常适合短期,高度精确的测量。他们可以检查微型零件,厚度和形状等。飞行时间传感器在更长的距离内工作,不受反射率或环境光的影响 - 非常适合将其定位为/RS,Rail Cars和Gantry Cranes。

生病的眩光传感器

The Glare sensor detects and distinguishes glare on even surfaces. It also provides maximum reliability and saves costs. Previously, gloss on object surfaces was a disruptive factor that regularly had engineers breaking into a sweat. Now, gloss properties are a distinguishing criterion for process control – regardless of color, transparency or pattern. And it will be engineers’ eyes that shine, not their brows. Equipped with intelligent Delta-S-Technology, Glare is a further milestone in customer-oriented sensor development. Once again, SICK is confirming its leading position in opto-electronic sensors for the detection of a range of objects.

生病的发光传感器

Luminescence sensors detect visible and non-visible marks that illuminate when using ultraviolet (UV) light. Fluorescent material and marks are reliably detected independently of their pattern, colors or surface conditions on any material. Luminescence sensors emit UV light with a wave length of approximately 375 nm. Fluorescent substances convert the UV light into long-wave visible light, which is then received and evaluated by the luminescence sensor.

Sick Non-contact motion sensors

Non-contact motion sensors directly detect the movements of object surfaces. This detection requires no scale or measuring elements. The surfaces therefore remain clean and undamaged, and objects remain free of wear and tear. The motion can be in any arbitrary direction, and linear or rotary. The detection is also independent of whether the object or sensor is moving.

Sick Capacitive and magnetic proximity sensors

接近传感器可提供各种物体和介质的非接触式检测。Sick的传感器非常适合工业应用和要求。Sick的电容和磁性接近传感器提供了较长的使用寿命,极端的坚固性和最高精度。智能,可靠地解决了特定于行业的自动化任务。

Sick Inductive proximity sensors

目前,几乎所有行业都在使用数百万个归纳接近传感器。他们检测到没有接触的金属物体,其特征是使用寿命长和极端的坚固性。借助最新的ASIC技术,SIX的传感器提供了精确和可靠性的最终。病态可以提供正确的解决方案,以满足您每次的要求 - 从具有单个,双重或三重操作距离的圆柱或矩形标准传感器到爆炸性区域和恶劣环境的特殊传感器。我们的传感器是针对任何涉及自动化的任务实施特定于行业和定制的解决方案的智能,可靠的途径。

Sick Traffic sensors

Added safety – fewer backups: These are the key requirements of traffic service providers. Intelligent traffic sensors are absolutely fundamental to ensuring state-of-the-art traffic guidance technology. With its sophisticated equipment for measuring visual range, visibility, and wind speed, as well as detecting overheight, SICK is helping to find solutions to these tasks.

病态的光电传感器

Sick的各种光电传感器提供精确的光学和先进技术,从而通过传感器智能创建了市场领先的解决方案。通过使用最新的SIRIC®和LED技术,这些传感器可提供最高水平的操作可靠性。其他传感器信息可用于简化现代生产过程。全球许多自动化应用程序都使用了广泛的光电传感器。

Sick Inertial sensors

Position data of objects is indispensable for the automation of processes, especially in demanding and mobile applications. SICK offers a wide range of inertial sensors for this purpose, for both simple static and highly dynamic applications.

Sick Magnetic cylinder sensors

病态的创新缸传感器。易于处理,模拟输出的选择,最佳的开关特性,在食品和饮料行业中使用的适用性,对最新IO-Link技术的支持以及我们全面的适配器,磁性缸传感器的全面安装选项从病人那里配备了所有安装位置和条件。

Sick Pattern sensors

The pattern sensor is a proximity-scanning opto-electronic sensor. Distinctive patterns in an image are used as a reference for the subsequent, accurate detection and positioning of objects. A stable switching signal is generated at high speeds with an intelligent algorithm for signal processing regardless of reference marks. It is typically used in the packaging industry.

Sick Fluid sensors

Optimized control of process parameters is the main driver for increasing efficiency and reducing input of valuable resources. Whether it’s pressure measurement, temperature measurement, level control or flow metering – SICK offers a wide range of solutions for measuring process variables for liquids, gases and bulk solids and protecting against overfill and dry run. SICK devices are rugged and easy to use. Innovative sensor technology enables accurate, universal measurement independent of material type.

Sick Safety radar sensors

生病的安全雷达传感器即使在恶劣的生产条件下,也可以使用非常高的机器可用性可靠的个人和对象检测。无论有火花,木屑,灰尘,热,冷还是其他干扰因素:病态的崎readar技术可确保高机器和植物生产力。

病态的电动反馈系统

Commutation, position and speed measurement with the corresponding number of interfaces used to require three sensors. Today, SICK motor feedback systems offer these functions in a single device. A consistent mechanical interface allows for a high level of flexibility. SICK motor feedback systems are also setting standards for electrical interfaces such as HIPERFACE® and HIPERFACE DSL®. They meet important requirements including temperature resistance, high resolution, and multiturn design. Certification to SIL2 permits implementation of the Machinery Directive as per EN ISO 13849.

Sick Analyzer solutions

SICK’s analyzer solutions provide forward-thinking concepts for measuring tasks in the fields of emission and process measurement technology. Typical fields of application include emission and process measurements in power plants, waste incineration plants, cement plants, and the chemical industry.

生病的本地化和定位解决方案

仓库和生产领域的逻辑过程必须有效。通过检测轨道和免费应用程序的位置和速度,对象的跟踪以及移动平台的本地化以及AGV系统机队的位置和速度,可以实现效率的显着提高。病人为这些目的提供了全面的本地化和定位解决方案。

Sick Detection and ranging solutions

The LiDAR (Light Detection and Ranging) laser measurement technology offers solutions for a wide range of applications. The two- or more-dimension contour data recorded can be processed both internally and externally. The technology is ideal for indoor and outdoor applications, for example anti-collision in ports, classification in traffic, detection in building automation, or position evaluation in navigation, for example.

病态识别解决方案

Product traceability and anti-counterfeiting solutions require reliable automatic identification products. SICK offers the three most common industrial identification technologies: laser-based scanners for 1D codes, image-based 1D and 2D code readers, and RFID readers. Integrated interfaces enable the readers to communicate inside industrial networks and innovative functionality makes commissioning and operation easy.

Sick System solutions

在实施用于工厂,物流和过程自动化的系统解决方案时,我们在组件中使用尖端技术。我们的服务范围涵盖了从想法和咨询到实施和现场售后服务的所有内容。我们的组件的高质量以及员工的奉献精神和专业知识验证了病假背后的核心概念:为要求任务的出色解决方案。

病流量测量技术

Flow measurement technology is used in nearly all industries. SICK has the tools to meet this many-faceted challenge and offers a comprehensive product portfolio of innovative sensor technology. Whether as custody transfer meters or measuring devices for monitoring and control: Flow measurement technology from SICK always works safely and reliably on the basis of the most up-to-date technology – even under difficult process and ambient conditions.

Sick Machine vision

视觉解决方案是自动检查和测量任务的理想选择。Sick的2D和3D视觉摄像机可用于解决需要测量,定位,检查和识别的广泛应用。我们的视觉产品是为工业环境而设计的,精心设计,旨在利用Sick在工业传感器上的60多年经验。