1.4

Rubber Suspension Units

Selection chart for rubber suspension standard elements

with Rubmix 10

Specification

DR-A 15 x 25

Effective element length

Size S

Inner square

Housing

General

• Light metal profiles: extruded profiles, seawater resistant (DIN 1725).

• Blue protection paint: water-soluble paint, coating thickness 40 – 80 µm.

• Fixation screws: minimum strength class of 8.8

• Welding on elements: do not weld on rubber suspensions – welding heat

will affect or destroy the rubber inserts – ask for customized elements

• Most of the elements can be supplied in stainless steel version – also

镀锌或特殊的油画avai版本lable.

Further customized elements: see examples on page 1.14 to 1.19.

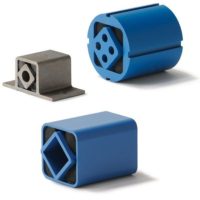

Inner square

Housing

A

Light metal profile,

as from size 60 in steel

C

Light metal profile

S

Steel tube for plug-in connection

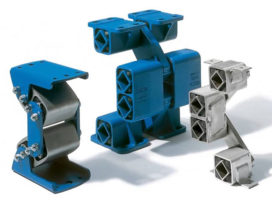

Accessories

for housing

Steel parts

DR

Steel tube

DR-A 15 to 50

Page 1.6

DR-C 15 to 50

Page 1.6

DR-S 11 to 50

Page 1.7

Bracket BR 11 to 50

Page 1.7

DK

Light metal profile

DK-A 15 to 50

Page 1.8

DK-C

on request

DK-S 11 to 50

Page 1.8

Bracket BK 11 to 50

Page 1.9

DW

Light metal profile

DW-A 15 to 38

Page 1.10

DW-C 15 to 38

Page 1.10

DW-S 15 to 38

Page 1.10

Accessories

for inner square A

Steel parts

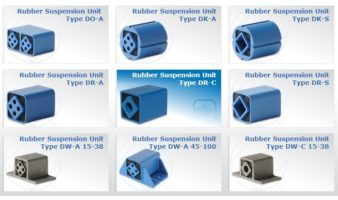

DW

Nodular cast iron

DW-A 45 and 50

Page 1.11

DW-C 45 and 50

on request

DW-S 45 and 50

Page 1.11

WS 11 to 50

Page 1.13

DW

Steel welded

construction

DW-A 60 to 100

Page 1.11

DO

Light metal profile

Size 50 in nodular

cast iron

DO-A 15 to 50

Page 1.12

DO-C

on request

DO-S

on request

Ideal for alternating mo-

tions over neutral element

position.

For sizes DR 15 – 45: Fixa-

每- tion通过2到4

sistent threaded bars (sizes

DR 27 – 45 also available

with threaded holes).

Friction locking of the core

by means of one central

bolt, can be positioned in

full 360° angle-range. For

ideal friction locking, please

remove paint cover on face

side. For alternating element

motion of max. ±10°.

For plug-in connection with

square profile*. Plug-in

length min. 2 x width

在平坦的“C”。Connection

is not recommendable by

alternating motions – play

between the plugged

squares.

* The square should be

made out of bright steel,

tolerance h9 – h11. Possi-

bly, the edges have to be

overwinded (edge-radius

in element profile max.

1.5 mm).

Specification

inner squares

Housing