2.9

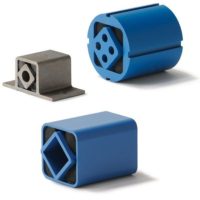

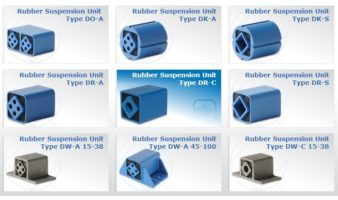

Oscillating Mountings

90°

±

1°

Technology

Determination of the average material conveying speed v

m

Main influencing factors:

–

Conveying ability of the

material

– Height of the bulk goods

– Screen box inclination

–

Position of unbalanced motors

–

Position of the center of gravity

The material speed on circular

motion screens does vary, due

to differing screen-box inclina-

tion angles.

•

Example:

The horizontal line out of the

intercept point of stroke

(7.7 mm) and motor revolutions

(960 rpm) is indicating an

average theoretical speed of

12.3 m/min or 20.5 cm/sec.

Alignment of the elements

If the suspensions for linear motion screens are arranged as

shown on page 2.7, a harmonic, noiseless oscillation of the

screen will result. The rocker arm fixed to the screen carries

out the greater part of the oscillations. The rocker arm fixed

to the substructure remains virtually stationary and ensures a

low natural frequency, and thereby also a good vibration

isolation. The mounting axis has to be arranged to be at

right angles

(90°) to the conveying axis, with maximum

tolerance of ±1°.

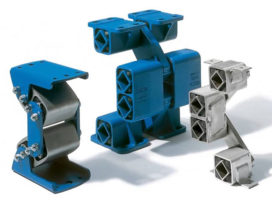

Resonance amplification and

continuous running

At the screen start-up and run-out the suspension elements

are passing through the resonance frequency. By the result-

ing amplitude superelevation the four rubber suspensions in

the AB mountings do generate a high level of damping

which is absorbing the remaining energy after only a few

strokes. The screen box stops its motion within seconds.

Laboratory measurements of a typical development of the

residual forces on a ROSTA screen suspension:

Screen box fixation

Substructure

cm/s

m/min

53

32

50

30

47

28

43

26

40

24

37

22

33

20

30

18

27

16

23

14

20

12

17

10

13

8

10

6

7

4

3

2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

9 g

8 g

7 g

6 g

5 g

4 g

3 g

2 g

n

s

= 720

n

s

= 960

n

s

= 1440

n

s

= 2880

Oscillating stroke sw [mm]

物料输送速度v

m

Diagram for angle of inclination

β

= 45°

to the horizontal

start-up

continuous running

run-out

vertical force

time

Oscillation

direction