5.14

ROSTA

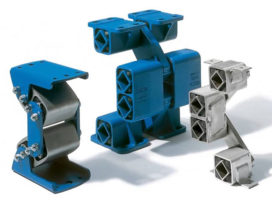

Motorbases in customized design

for special applications

Fan drive in heat exchanger with vertically

installed motor on MB 50, special

The MB 50 had been equipped with an additional

bronze glide bearing to assure the axial position

of the motor on the elastic ROSTA element.

Installation of cooling compressors in

busses on MB 45 special, equipped with

heat-resistant elastic inserts Rubmix 40

In this specific application, the ROSTA Motorbase is fulfilling

two main functions: keeps the belt tightened between Diesel-

engine and cooling compressor, does prevent the transmission

of compressor vibrations into the bus chassis.

ROSTA

Calculation:

Tensioning Motorbase

D, R

diameter and radius of the driven puley, D=

280 mm

d, r

diameter and radius of the drive puley (above the ROSTA element), d=

190 mm

n

speed of the drive puley (above the ROSTA element)

2040 rpm

P

power of the motor above the ROSTA element

45 kW

i

factor of the overturning torque (during start of the motor)

2.3 -

Pi

max. required power during the start process of the motor = P * i

103.5 kW

A

distance of the puleys

calculation 1

mm

X

horizontal distance of the puleys

700 mm

Y

vertical distance of the puleys

300 mm

a

half of the belt opening angle

calculation 2

°

F

Rv

belt force for pretensioning one belt

721 N

F

Rm

belt force for the running process of one belt

721 N

s

F

resulting lever for tensioning the belts

214 mm

s

R

resulting lever of the puled belt

308 mm

z

number of belts

3 -

M

Sv

tensioning moment during pretension process

calculation 3

Nm

M

Sm

tensioning moment during running process

calculation 4

Nm

M

P

torque out of the power

calculation 5

Nm

calculation 1

762 mm

calculation 2

3.4 °

calculation 3

924 Nm

calculation 4

924 Nm

calculation 5

1571 Nm

max. torque to the ROSTA element

1571

Nm

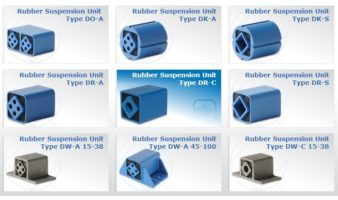

element choice

DR 50x400

0

50

100

150

200

250

300

350

400

450

-200

0

200

400

600

800

1000

y [mm]

x [mm]

d=190

n=2040

P=45

D=280

A=579

s

F

=200

s

R1

=293

center of the ROSTA element

s

R2

= 308

Motorbases