<以前的rexnord圆顶链|产品指数|下一个rexnord圆顶链>

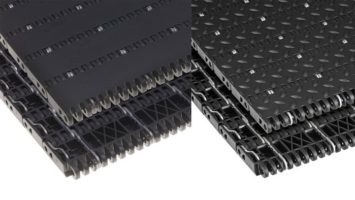

7700系列1英寸桨距重型带用于各种各样的应用。由于其强大的设计,这些皮带对于玻璃工程和汽车行业很常见。7700系列封闭,两个开放,

橡胶顶部和LBP执行。对于单个车道,可以使用带有标签引导件的多个模具到宽度执行。对于玻璃作品和饮料行业的应用,动态转移系统是一种经过验证的解决方案。作为标准,皮带供应高性能缩醛和聚丙烯。

特征

•强大的½英寸厚模块设计意味着非常高的强度。

•HP缩醛可减少摩擦,提供出色的耐磨性,并产生干燥运行的可能性。

•圆形外边缘,以获得更好的侧面转印和改进的产品处理。

• 扭锁TM值通过铰接插头销钉防止插头损耗,并允许轻松访问安装和维护。

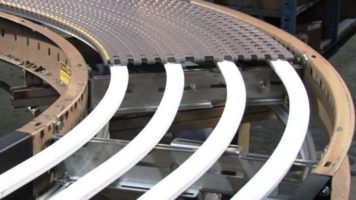

•动态传输系统(DTS®)创建平滑的90°传输。

•皮带和链轮设计确保了最佳的接合和可靠的驱动器。

![]()

•7700系列带由FTM 1055或FT 1055 Cloughbelts伴随,在直线运行和侧面夹的输送机之间进行完美匹配;1055也可以由NS 7700链轮驱动。

程序 |

|

7705 Solid Top |

封闭的表面;对于重型玻璃和PET应用,公制版可以可选地配备积极痕迹 |

7706穿孔顶部 |

8%开放区;因为其他人可以处理 |

7708穿孔顶部 |

20%开放区域;在其他人之间,温暖者和冷却器 |

7705橡胶顶部 |

对于倾斜和下降的输送机,高达20°;可应要求提供 |

积极痕迹 |

用于精确引导传送带中的带(仅限度量和DTS)的标签 |

DTS® |

Single module Dynamic Transfer System for left- or right hand self-clearing transfers to avoid dead plates at 90° transfers; as a standard equipped with Positrack guiding |

7700-Series MatTop®Chains

瓶子转移7705腰带

带TCF7705皮带的输送机

![]()

Assembly |

皮带型 |

代码* |

温度范围°C |

工作负载(最大) |

重量 |

Backflex半径(min。) |

|

干燥 |

湿的 |

n / m(21°C) |

kg / m.2 |

mm |

|||

对于最苛刻的装瓶和集装箱应用,REXORD桌面和哑光链的性能和生产力没有替代。自1938年以来,随着地面突破的815台桌面不锈钢直连链,REXNORD在饮料和食品输送方面拥有良好的创新,为全球客户提供了激发忠诚和驱动的忠诚和驱动规范。

Line efficiency

高速的平滑容器流动对于提高线效率并防止产品损坏至关重要。特别是当从多个通道或反向移动时,玻璃瓶的温和载玻片横跨超平,高度抛光的不锈钢Rexnord链条可以显着贡献饮料生产线的质量和效率。

饮料中的应用

Rexnord products cover a wide variety of applications like: general conveying of glass bottles one-way and return, PET bottles and other plastic containers, jars, cans 2- and 3-piece, crates, plastic containers, boxes, shrink-wrapped packages.

产品简介

Rexnord offers a comprehensive of conveyor products which include

Metal TableTop chain

塑料桌面链包括LBP和Supergrip

Plastic MatTop chain in standard, small pitch and heavy duty alternatives.

MagnetFlex角轨道以及标签和斜角曲线等替代方案

机加工和模制链轮

高性能聚合物材料和经济替代品,适用于苛刻的应用

Pack and case conveying that offers flexibility of line configurations and total system cost efficiencies can significantly improve productivity at the dry end of filling lines. At the same time, brand extensions, innovative packaging, and light weight packaging materials are driving more demanding performance in pack and case handling. Cases and packs must be protected from damage even as they move rapidly out of case packers and shrink wrap machines and into, around, and out of curves.

That’s why Rexnord’s case and package handling conveying chains come in our modular small pitch, lightduty 15mm 1500 Series to medium duty 25.4mm pitch 1000 Series to the heavy-duty 1 in pitch 1005 Series in both versions for general conveying and in Super Grip / RubberTop™ versions for metering, incline, decline and braking applications. Furthermore the programm includes a comprehensive portfolio of Sideflexing MatTop chains like the versatile 1200-series MatTop. For accumulating conveyor the LBP (Low Backline Pressure) chains offers a solution to a large variety of applications.

随着Rexnord原始重型桌面包装输送,没有其他公司为您的案例和包装处理要求提供传送解决方案的宽度。

Rexnord products are known for their reliable performance in though conditions and challenging applications due to their robustness in design and drive technology. In container making therefore Rexnord products are often the preferred choice for applications like vacuum elevators, high speed (magnetic) conveyors, UV applications, high temperature applications and inspection conveyors.

Rexnord材料创新

On top Rexnord offers the most comprehensive material portfolio in the market to meet an extensive variety of application requirements. Several applications in glassworks and container making lines combine an abrasive environment with the need for smooth container handling. Often these applications can not be easily lubricated to neutralize the effect of the hard abrasive particles in the environment. Therefore specialized materials can be part of a custom made solution. This is why, besides several proven specialized high performance materials like WX, HP and PS, Rexnords material portfolio is now completed with DKA aramid reinforced material.

使用较低的生命周期成本,更少的停机时间和减少产品废物的加工和包装食品需要人员,技术和工艺,使工厂效率和生产力成为一个目标。

在这方面的传送技术是每种食品加工厂的重要组成部分。随着输送链和部件在加工过程中与食物直接接触,它们强烈促成植物工艺卫生。基于声音卫生设计的易于清洁的输送链有助于更好的食品安全,同时通过更有效的清洁降低成本。此外,链条的可靠性和鲁棒性强烈贡献了加工线的升高时间。

Rexnord食品输送链技术和食品安全材料创新为各种食品制造厂提供高生产率解决方案,可用于各种食品制造厂的食品应用。这就是为什么Rexnord的510,1010,1200和2010系列Mattop®链带来了各种食品设计和易于清洁的功能,可以成为每种食品加工厂稳健且有效的食品安全计划的重要组成部分。

Rexnord的汽车解决方案在多年来一直在多个行业传达技术经验。从机械压力机到最终检查输送机,REXNORD为您的应用开发了低维护模块化链解决方案。通过评估您的个人需求和目标,Rexnord的熟练工程师将帮助您获得最低的总体拥有成本(TCO),通过提高运营安全,效率和生产力,产生显着的成本。

REXNORD 6990系列混合哑光链

6990系列混合热带丛林p Chain (patent pending) is designed for automotive conveyors with high loads or frequent load variations (people movers). The steel structure in the chain creates stiffness and strength enabling the chain to be used in conveyors with lengths over 328-feet (100m) (moving people, vehicles or a combination of the two).

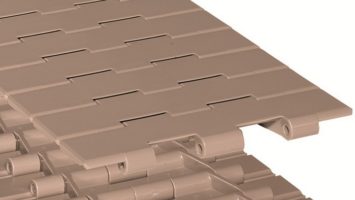

Rexnord 3120系列哑光链

3120系列哑光链主要用于工业型应用:洗车,滑雪处理,人员搬运工,托盘处理和汽车部件处理。坚固的设计采用高强度缩醛材料模塑,采用Rexnord的扭锁销保持系统。

Rexnord 3180系列哑光链

Rexnord认识到机会在SkID应用中轻松和经济地转换现有技术的重要性,并开发了3180系列哑光链。这些链适用于3.2英寸(81毫米)的滑动输送机,允许在转移到下一个输送机之前机械地对齐。

在隧道山口,加热器和冷却器中成功加工需要通过隧道山宫探测器的高度可靠,控制传送,并在进给和备用外部的平滑容器转移。To have the highest conveying chain reliability, to eliminate product waste from tipped or broken containers, and to achieve durable conveying performance, Rexnord’s 2000-series USP MatTop chain and the Rexnord’s 9200 series Fortrex Stainless Steel MatTop Chain are specifically designed for superior performance in the demanding environment of pasteurizers, warmers and coolers.

DTS-C动态和外部传输

通过REXNORD专利的DTS-C将特殊的转移梳子和/外送链相结合到主REXNORD Pasteureiler皮带中,以进行全自动清除转移。这消除了死区区域,并确保了连续的产品流消除了背部压力和潜在的产品损坏。

USP超稳定聚丙烯材料

USP材料是一种独特的稳定剂和抗氧化剂的配方,可保护链的聚丙烯材料免受热和/或化学品引起的降解。USP材料在整个连锁生命周期中提高了可靠性,并有助于避免出现未安排停机的风险。

积极痕迹中心指南

Patented integrated center guiding lugs ensure optimum chain tracking and keeps the chain sides from touching the tunnel structure, and eliminates the need to lock sprockets on the shaft.