<以前的Rexnord Flattop链|产品指数|Next Rexnord FlatTop Chains >

Classic Sprockets

潮湿的经典链轮,

![]()

![]()

![]()

![]()

1000-Series

诸如巴氏杀菌之类的热应用

链轮类型 |

代码编号 |

Number of Teeth |

bore b |

Pitch Diameter E |

Outside Diameter F |

集线器宽度a |

mm/inch |

mm |

mm |

mm |

|||

圆孔 |

||||||

CS 1000 12-30 |

895.02.17 |

12 |

30毫米 |

98.1 |

96.5 |

20 |

CS 1000 12-40 |

895.02.11 |

12 |

40 mm |

|||

CS 1000 12-50 |

895.02.12 |

12 |

50毫米 |

|||

CS 1000 18-30 |

895.08.17 |

18 |

30毫米 |

146.3 |

145.9 |

|

CS 1000 18-35 |

895.08.10 |

18 |

35 mm |

|||

CS 1000 18-40 |

895.08.11 |

18 |

40 mm |

|||

CS 1000 18-45 |

895.08.15 |

18 |

45 mm |

|||

CS 1000 18-50 |

895.08.12 |

18 |

50毫米 |

|||

CS 1000 18-65 |

895.08.13 |

18 |

65 mm |

30 |

||

CS 1000 20-35 |

895.09.10 |

20 |

35 mm |

162.4 |

161.7 |

20 |

CS 1000 20-40 |

895.09.11 |

20 |

40 mm |

|||

CS 1000 20-50 |

895.09.12 |

20 |

50毫米 |

|||

CS 1000 12-1 |

895.02.46 |

12 |

1.0 |

98.1 |

96.5 |

|

CS 1000 18-1 |

895.08.46 |

18 |

1.0 |

146.3 |

145.9 |

|

CS 1000 18-1½ |

895.08.41 |

18 |

1.5" |

|||

CS 1000 18-2 |

895.08.42 |

18 |

2.0" |

|||

CS 1000 20-1 |

895.09.46 |

20 |

1.0 |

162.4 |

161.7 |

|

CS 1000 20-1½ |

895.09.41 |

20 |

1.5" |

|||

方孔 |

||||||

CS 1000 18-40x40 |

895.08.21 |

18 |

40 mm |

146.3 |

145.9 |

20 |

CS 1000 18-60x60 |

895.08.28 |

18 |

60 mm |

30 |

||

CS 1000 18-65x65 |

895.08.23 |

18 |

65 mm |

|||

CS 1000 20-40x40 |

895.09.21 |

20 |

40 mm |

162.4 |

161.7 |

20 |

CS 1000 20-60x60 |

895.09.28 |

20 |

60 mm |

30 |

||

CS 1000 20-65x65 |

895.09.23 |

20 |

65 mm |

|||

CS 1000 12-1½x1½ |

895.02.51 |

12 |

1.5" |

98.1 |

96.5 |

20 |

CS 1000 18-1½x1½ |

895.08.51 |

18 |

1.5" |

146.3 |

145.9 |

|

CS 1000 20-1½x1½ |

895.09.51 |

20 |

1.5" |

162.4 |

161.7 |

|

潮湿的经典链轮,诸如巴氏杀菌之类的热应用 |

||||||

方孔 |

||||||

CS 1000 12-40x40 POM |

893.02.21 |

12 |

40 mm |

98.1 |

96.5 |

20 |

CS 1000 18-40x40POM |

893.08.21 |

18 |

40 mm |

146.3 |

145.9 |

20 |

CS 1000 18-60x60 POM |

893.08.28 |

18 |

60 mm |

30 |

||

CS 1000 20-40x40 POM |

893.09.21 |

20 |

40 mm |

162.4 |

161.7 |

20 |

CS 1000 20-60x60 POM |

893.09.28 |

20 |

60 mm |

30 |

||

![]()

For the most demanding bottling and container applications, there is no substitute for the performance and productivity of Rexnord TableTop and MatTop Chains. Since 1938, with the ground-breaking 815 TableTop stainless steel straight-running chain, Rexnord has pioneered innovation in beverage and food conveying that has inspired loyalty and driven specification for Rexnord conveyor chains from customers around the globe.

Line efficiency

高速平滑的容器流对于提高线路效率和防止产品损坏至关重要。尤其是在从多个车道转移到单个车道或反向时,瓶中的瓶装柔和滑梯横穿超灯,高度抛光的不锈钢雷克斯诺德链会对您的饮料生产线的质量和效率产生重大贡献。

饮料中的应用

Rexnord products cover a wide variety of applications like: general conveying of glass bottles one-way and return, PET bottles and other plastic containers, jars, cans 2- and 3-piece, crates, plastic containers, boxes, shrink-wrapped packages.

产品介绍

Rexnord offers a comprehensive of conveyor products which include

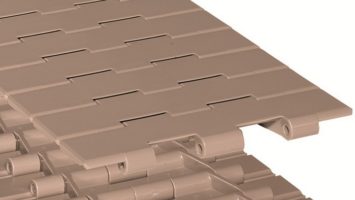

Metal TableTop chain

Plastic TableTop chain including LBP and Supergrip

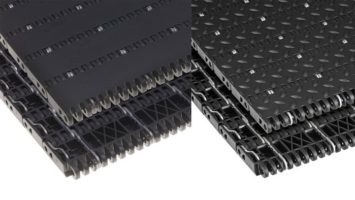

Plastic MatTop chain in standard, small pitch and heavy duty alternatives.

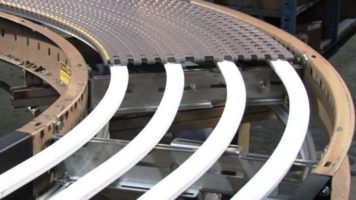

MagnetFlex角轨道以及诸如TAB和斜角曲线之类的替代方案

加工和模制链轮

高性能聚合物材料和经济替代方案,用于较少要求的应用

包和输送提供的灵活性line configurations and total system cost efficiencies can significantly improve productivity at the dry end of filling lines. At the same time, brand extensions, innovative packaging, and light weight packaging materials are driving more demanding performance in pack and case handling. Cases and packs must be protected from damage even as they move rapidly out of case packers and shrink wrap machines and into, around, and out of curves.

That’s why Rexnord’s case and package handling conveying chains come in our modular small pitch, lightduty 15mm 1500 Series to medium duty 25.4mm pitch 1000 Series to the heavy-duty 1 in pitch 1005 Series in both versions for general conveying and in Super Grip / RubberTop™ versions for metering, incline, decline and braking applications. Furthermore the programm includes a comprehensive portfolio of Sideflexing MatTop chains like the versatile 1200-series MatTop. For accumulating conveyor the LBP (Low Backline Pressure) chains offers a solution to a large variety of applications.

借助Rexnord原始重型桌链用于包装运输,没有其他公司提供针对您的案件和包装处理要求的解决方案的广度。

Rexnord products are known for their reliable performance in though conditions and challenging applications due to their robustness in design and drive technology. In container making therefore Rexnord products are often the preferred choice for applications like vacuum elevators, high speed (magnetic) conveyors, UV applications, high temperature applications and inspection conveyors.

Rexnord材料创新

On top Rexnord offers the most comprehensive material portfolio in the market to meet an extensive variety of application requirements. Several applications in glassworks and container making lines combine an abrasive environment with the need for smooth container handling. Often these applications can not be easily lubricated to neutralize the effect of the hard abrasive particles in the environment. Therefore specialized materials can be part of a custom made solution. This is why, besides several proven specialized high performance materials like WX, HP and PS, Rexnords material portfolio is now completed with DKA aramid reinforced material.

以较低的生命周期成本,减少的停机时间和减少产品浪费的加工和包装食品需要人员,技术和流程,以使植物效率和生产力达到第一的目标。

Conveying technology in this respect is a vital part in every food processing plant. As conveying chain and components come into direct contact with food during processing, they strongly contribute to plant process hygiene. Easy-to-clean conveying chain, based on sound hygienic design, contributes to better food safety while at the same time reducing costs through more effective cleaning. Further the reliability and robustness of the chain strongly contribute to the up time of the processing line.

Rexnord食品输送链技术和食品安全材料创新为整个食品制造工厂提供了高生产力解决方案。这就是为什么Rexnord的510、1010、1200和2010系列Mattop®连锁店及其食品磨牙设计和易于清洁的功能,这可能是每个食品加工厂中强大而有效的食品安全计划的重要组成部分。

Rexnord’s automotive solutions build on more than 100 years of conveying technology experience across multiple industries. From the mechanical press to the final inspection conveyors, Rexnord has developed low maintenance modular chain solutions for your applications. By assessing your individual needs and objectives, Rexnord’s skilled engineers will help you obtain the lowest Total Cost of Ownership (TCO), resulting in significant cost savings by improving operational safety, efficiency and productivity.

Rexnord 6990 Series Hybrid MatTop Chain

The 6990 Series Hybrid MatTop Chain (patent pending) is designed for automotive conveyors with high loads or frequent load variations (people movers). The steel structure in the chain creates stiffness and strength enabling the chain to be used in conveyors with lengths over 328-feet (100m) (moving people, vehicles or a combination of the two).

Rexnord 3120系列Mattop链

The 3120 Series MatTop Chain is primarily used for industrial type applications: car washes, skid handling, people movers, pallet handling, and automotive parts handling. The sturdy design is molded in high-strength acetal material and utilizes Rexnord’s Twistlock pin retention system.

Rexnord 3180系列Mattop链

Rexnord recognizes the importance of opportunities to easily and economically convert from existing technology in skid applications and has developed the 3180 Series MatTop Chain. These chains are suitable for 3.2 inch (81mm) skid conveyors, allowing the skids to be aligned mechanically before transferring to the next conveyor.

在隧道巴氏菌,加热器和冷却器中成功加工需要高度可靠的,通过隧道巴斯德式巴氏杀剂传递,并在输液和外喂食处进行光滑的容器转移。To have the highest conveying chain reliability, to eliminate product waste from tipped or broken containers, and to achieve durable conveying performance, Rexnord’s 2000-series USP MatTop chain and the Rexnord’s 9200 series Fortrex Stainless Steel MatTop Chain are specifically designed for superior performance in the demanding environment of pasteurizers, warmers and coolers.

DTS-C Dynamic In- and Outfeed Transfer

DTS-C patented by Rexnord combines special transfer combs and in/outfeed chains to the main Rexnord Pasteurizer belt for full self clearing transfers. This eliminates the dead plate area and ensures a continuous product flow eliminating back line pressure and potential product damage.

USP Ultra Stabilized Polypropylene Material

USP material is a unique formulation of stabilizers and anti-oxidants which protects the chain’s polypropylene material from degradation due to heat and/or chemicals. The USP material increases the reliability throughout the chain life cycle and helps to avoid the risk of unscheduled downtime.

PoSitrack Center向导

Patented integrated center guiding lugs ensure optimum chain tracking and keeps the chain sides from touching the tunnel structure, and eliminates the need to lock sprockets on the shaft.