<之前s Rexnord FlatTop Chains|Products index|Next Rexnord FlatTop Chains >

Application

Plate Top Chain Type |

Clean, dry, 轻松的工作 |

Clean, wet, light duty |

Abrasive, dry, 轻松的工作 |

Abrasive, wet, light duty |

Clean, dry, heavy duty |

清洁,潮湿,重型 |

Abrasive, dry, heavy duty |

Abrasive, wet, heavy duty |

Incline conveyor |

1864 |

|||||||||

1864 SS |

|||||||||

963 |

|||||||||

843 |

|||||||||

1843 TAB |

|||||||||

1874标签 |

|||||||||

1873标签,LF顶板 |

|||||||||

1873 TAB, BWX Top Plate |

|||||||||

3873 TAB |

|||||||||

HFP 1873 TAB |

Application

Gripper Chain Type |

Small empty product elevator |

小型产品电梯 |

Large empty product elevator |

Large full product elevator |

High load, abrasive application |

Rinser application, ambient |

冲洗应用,高温 |

1874标签, Stainless Steel Top Plate |

|||||||

1874标签HD, Stainless Steel Top Plate |

|||||||

1843 TAB, LF top plate |

|||||||

1873 TAB, HP top plate |

|||||||

1873 TAB, LF top plate |

![]()

Steel base chains are recommended for dry applications, stainless steel base chains are recommended for wet applications.

Optional

Best choice

![]()

Chain Type |

Code Number |

Plate Width A |

Weight |

Loose Top Plate |

Working Load (max.) |

Connection Link |

||

毫米 |

inch |

kg/m |

Code Number |

N (21°C) |

Type |

Code Number |

||

Steel Top Plate/Steel Base Chain |

||||||||

1864-K325 |

814036213 |

82.5 |

3.25 |

3.33 |

514-113-13 |

4500 |

CL-1864 CA |

514-331-1 |

1864-K450 |

814036219 |

114.3 |

4.50 |

4.00 |

514-113-19 |

|||

1864-K600 |

814036223 |

152.4 |

6.00 |

4.40 |

514-113-23 |

|||

1864-K750 |

814036225 |

190.5 |

7.50 |

4.80 |

514-113-25 |

|||

Stainless Steel Top Plate/Stainless Steel Base Chain |

||||||||

1864 SS-K325 |

814036313 |

82.5 |

3.25 |

3.33 |

514-114-13 |

3400 |

CL-1864 SS |

514-115-1 |

1864 SS-K450 |

814036319 |

114.3 |

4.50 |

4.00 |

514-114-19 |

|||

1864 SS-K600 |

814036323 |

152.4 |

6.00 |

4.40 |

514-114-23 |

|||

1864 SS-K750 |

814036325 |

190.5 |

7.50 |

4.80 |

514-114-25 |

|||

![]()

![]()

![]()

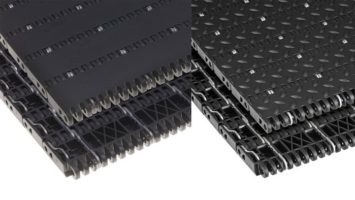

PlateTop Chains

Standard length: 3.048 m – 10 feet (160 links). Min. backflex radius 305 mm.

For the most demanding bottling and container applications, there is no substitute for the performance and productivity of Rexnord TableTop and MatTop Chains. Since 1938, with the ground-breaking 815 TableTop stainless steel straight-running chain, Rexnord has pioneered innovation in beverage and food conveying that has inspired loyalty and driven specification for Rexnord conveyor chains from customers around the globe.

线效率

Smooth container flow at high speeds is essential to increase line efficiency and preventing product damage. Especially when moving from multiple to single lanes or the reverse, the gentle slide of bottles across ultra-flat, highly polished stainless steel Rexnord chain can contribute significantly to the quality and efficiency of your beverage production line.

Applications in beverage

Rexnord产品涵盖各种应用,如:玻璃瓶一般输送单向和返回,宠物瓶和其他塑料容器,罐子,罐头2-和3件式,板条箱,塑料容器,盒子,收缩包装的包装。

Product Portfolio

REXNORD提供了全面的传送带产品,包括

金属桌面链

Plastic TableTop chain including LBP and Supergrip

塑料哑光链标准,小沥青和重型替代品。

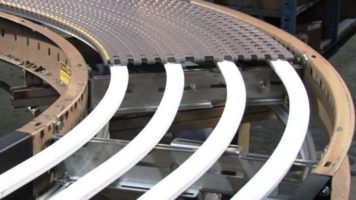

Magnetflex Corner tracks as well as alternatives like Tab and Bevel curves

Machined and moulded sprockets

High performance polymer materials & economic alternatives for less demanding applications

包装和案例输送,可提供线路配置和总系统成本效率的灵活性,可以显着提高填充线干末端的生产率。同时,品牌延伸,创新包装和轻量级包装材料在包装和案例处理中驾驶更苛刻的性能。案例和包装必须保护免受损坏,即使它们迅速超出案例包装器和收缩包装机以及周围的曲线和曲线。

That’s why Rexnord’s case and package handling conveying chains come in our modular small pitch, lightduty 15mm 1500 Series to medium duty 25.4mm pitch 1000 Series to the heavy-duty 1 in pitch 1005 Series in both versions for general conveying and in Super Grip / RubberTop™ versions for metering, incline, decline and braking applications. Furthermore the programm includes a comprehensive portfolio of Sideflexing MatTop chains like the versatile 1200-series MatTop. For accumulating conveyor the LBP (Low Backline Pressure) chains offers a solution to a large variety of applications.

With the Rexnord original Heavy Duty TableTop chains for packaging conveying, no other company provides the breadth of conveying solutions for your case and package handling requirements.

REXNORD产品在其可靠的性能中,虽然是由于其在设计和驱动技术的鲁棒性导致的条件和具有挑战性的应用。因此,在集装箱制作中,REXORD产品通常是真空电梯,高速(磁性)输送机,UV应用,高温应用和检查输送机等应用的首选。

Rexnord Material innovation

Top Rexnord在市场上提供最全面的材料产品组合,以满足广泛的应用要求。玻璃厂和集装箱制造线的几种应用结合了磨料环境,需要平滑容器处理。通常,这些应用不能容易地润滑以中和硬磨粒在环境中的效果。因此,专业材料可以是定制解决方案的一部分。这就是为什么除了WX,HP和PS这样的若干经过验证的专业高性能材料外,REXNORDS材料产品组合现已完成DKA芳纶加固材料。

Processing and packaging food faster with a lower life-cycle cost, less downtime, and reduced product waste requires people, technology, and processes working together to make plant efficiency and productivity the number one goal.

Conveying technology in this respect is a vital part in every food processing plant. As conveying chain and components come into direct contact with food during processing, they strongly contribute to plant process hygiene. Easy-to-clean conveying chain, based on sound hygienic design, contributes to better food safety while at the same time reducing costs through more effective cleaning. Further the reliability and robustness of the chain strongly contribute to the up time of the processing line.

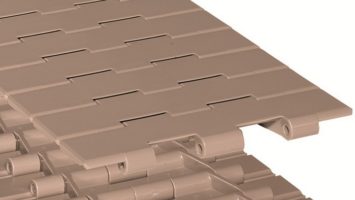

Rexnord food conveying chain technology and food-safe material innovations offer high productivity solutions for food applications throughout each food manufacturing plant. That is why Rexnord’s 510, 1010, 1200 and 2010 Series MatTop® Chain, with their foodgrade design and easy-to-clean features, can be an important part of a robust and effective food safety program in every food processing plant.

建立在以上Rexnord汽车解决方案100 years of conveying technology experience across multiple industries. From the mechanical press to the final inspection conveyors, Rexnord has developed low maintenance modular chain solutions for your applications. By assessing your individual needs and objectives, Rexnord’s skilled engineers will help you obtain the lowest Total Cost of Ownership (TCO), resulting in significant cost savings by improving operational safety, efficiency and productivity.

Rexnord 6990 Series Hybrid MatTop Chain

The 6990 Series Hybrid MatTop Chain (patent pending) is designed for automotive conveyors with high loads or frequent load variations (people movers). The steel structure in the chain creates stiffness and strength enabling the chain to be used in conveyors with lengths over 328-feet (100m) (moving people, vehicles or a combination of the two).

Rexnord 3120 Series MatTop Chain

The 3120 Series MatTop Chain is primarily used for industrial type applications: car washes, skid handling, people movers, pallet handling, and automotive parts handling. The sturdy design is molded in high-strength acetal material and utilizes Rexnord’s Twistlock pin retention system.

Rexnord 3180 Series MatTop Chain

Rexnord recognizes the importance of opportunities to easily and economically convert from existing technology in skid applications and has developed the 3180 Series MatTop Chain. These chains are suitable for 3.2 inch (81mm) skid conveyors, allowing the skids to be aligned mechanically before transferring to the next conveyor.

Successful processing in tunnel pasteurizers, warmers and coolers requires highly reliable, controlled conveying through the tunnel pasteurizer, and smooth container transfers at the infeed and outfeed. To have the highest conveying chain reliability, to eliminate product waste from tipped or broken containers, and to achieve durable conveying performance, Rexnord’s 2000-series USP MatTop chain and the Rexnord’s 9200 series Fortrex Stainless Steel MatTop Chain are specifically designed for superior performance in the demanding environment of pasteurizers, warmers and coolers.

DTS-C Dynamic In- and Outfeed Transfer

DTS-C patented by Rexnord combines special transfer combs and in/outfeed chains to the main Rexnord Pasteurizer belt for full self clearing transfers. This eliminates the dead plate area and ensures a continuous product flow eliminating back line pressure and potential product damage.

USP Ultra Stabilized Polypropylene Material

USP material is a unique formulation of stabilizers and anti-oxidants which protects the chain’s polypropylene material from degradation due to heat and/or chemicals. The USP material increases the reliability throughout the chain life cycle and helps to avoid the risk of unscheduled downtime.

PosiTrack centre guides

Patented integrated center guiding lugs ensure optimum chain tracking and keeps the chain sides from touching the tunnel structure, and eliminates the need to lock sprockets on the shaft.