<先前Rexnord FlatTop Chains|产品index|下一个Rexnord Flattop链>

1710 TAB K

![]()

![]()

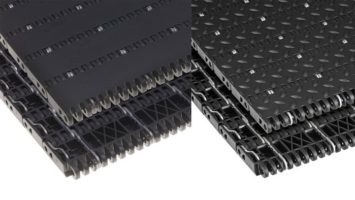

Multiflex Chains

Chain Type |

Code Number |

Link Width A |

Weight |

工作负载(最大) |

Backflex Radius (min) |

侧面半径(最小) |

|

mm |

inch |

kg/m |

N(21°C) |

mm |

mm |

||

WLF-Acetal |

|||||||

WLF 1710 TAB K |

L1710wlftabk |

98.0 |

3.86 |

1.93 |

2600 |

0 |

140 |

Standard length: 10 m - 32.8 feet (200 links). Top plate grey polyamide.

![]()

PAG。85

![]()

PAG。83,84

![]()

PAG。85

![]()

![]()

PAG。125

PAG。83,84

![]()

![]()

Chain Type |

Code Number |

Link Width A |

Weight |

工作负载(最大) |

Backflex Radius (min) |

侧面半径(最小) |

|

mm |

inch |

kg/m |

N(21°C) |

mm |

mm |

||

WLF-Acetal |

|||||||

WLF 1713 K |

L1713WLFK |

253.0 |

9.96 |

2.70 |

2600 |

1000 |

500 |

Multiflex Chains

Standard length: 10 m - 32.8 feet (200 links). Top plate white acetal.

PAG。83,84

![]()

对于最苛刻的装瓶和容器应用程序,无法代替Rexnord桌面和Mattop链的性能和生产力。自1938年以来,Rexnord凭借着突破性的815台桌不锈钢直线连锁连锁店,开创了饮料和食品运输的创新,这激发了全球客户的Rexnord输送链的忠诚度和驱动的规格。

Line efficiency

Smooth container flow at high speeds is essential to increase line efficiency and preventing product damage. Especially when moving from multiple to single lanes or the reverse, the gentle slide of bottles across ultra-flat, highly polished stainless steel Rexnord chain can contribute significantly to the quality and efficiency of your beverage production line.

Applications in beverage

Rexnord products cover a wide variety of applications like: general conveying of glass bottles one-way and return, PET bottles and other plastic containers, jars, cans 2- and 3-piece, crates, plastic containers, boxes, shrink-wrapped packages.

Product Portfolio

Rexnord offers a comprehensive of conveyor products which include

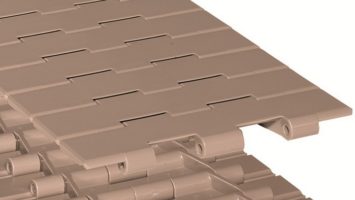

Metal TableTop chain

塑料桌链,包括LBP和SuperGrip

Plastic MatTop chain in standard, small pitch and heavy duty alternatives.

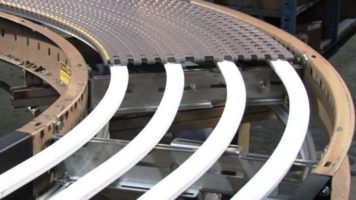

Magnetflex Corner tracks as well as alternatives like Tab and Bevel curves

Machined and moulded sprockets

High performance polymer materials & economic alternatives for less demanding applications

包装和案例输送提供线条配置的灵活性和系统成本效率的灵活性可以显着提高填充线干端的生产率。同时,品牌扩展,创新的包装和轻巧的包装材料在包装和外壳处理方面的性能更高。即使案件和包装迅速从箱子包装工和收缩包裹机中移出,并在曲线周围,周围和外出。

That’s why Rexnord’s case and package handling conveying chains come in our modular small pitch, lightduty 15mm 1500 Series to medium duty 25.4mm pitch 1000 Series to the heavy-duty 1 in pitch 1005 Series in both versions for general conveying and in Super Grip / RubberTop™ versions for metering, incline, decline and braking applications. Furthermore the programm includes a comprehensive portfolio of Sideflexing MatTop chains like the versatile 1200-series MatTop. For accumulating conveyor the LBP (Low Backline Pressure) chains offers a solution to a large variety of applications.

With the Rexnord original Heavy Duty TableTop chains for packaging conveying, no other company provides the breadth of conveying solutions for your case and package handling requirements.

Rexnord products are known for their reliable performance in though conditions and challenging applications due to their robustness in design and drive technology. In container making therefore Rexnord products are often the preferred choice for applications like vacuum elevators, high speed (magnetic) conveyors, UV applications, high temperature applications and inspection conveyors.

Rexnord Material innovation

Rexnord顶部提供了最全面的母亲ial portfolio in the market to meet an extensive variety of application requirements. Several applications in glassworks and container making lines combine an abrasive environment with the need for smooth container handling. Often these applications can not be easily lubricated to neutralize the effect of the hard abrasive particles in the environment. Therefore specialized materials can be part of a custom made solution. This is why, besides several proven specialized high performance materials like WX, HP and PS, Rexnords material portfolio is now completed with DKA aramid reinforced material.

Processing and packaging food faster with a lower life-cycle cost, less downtime, and reduced product waste requires people, technology, and processes working together to make plant efficiency and productivity the number one goal.

在这方面传达技术是每个食品加工厂的重要组成部分。随着输送链和组件在加工过程中与食物直接接触,它们会有助于植物过程卫生。基于声音卫生设计的易于清洁的输送链,可以改善食品安全,同时通过更有效的清洁来降低成本。进一步,链的可靠性和鲁棒性强烈有助于加工线的UP时间。

Rexnord food conveying chain technology and food-safe material innovations offer high productivity solutions for food applications throughout each food manufacturing plant. That is why Rexnord’s 510, 1010, 1200 and 2010 Series MatTop® Chain, with their foodgrade design and easy-to-clean features, can be an important part of a robust and effective food safety program in every food processing plant.

Rexnord的汽车解决方案建立在超过100年的多个行业的技术经验的基础上。从机械出版社到最终检查输送机,Rexnord已为您的应用开发了低维护模块化链解决方案。通过评估您的个人需求和目标,Rexnord的熟练工程师将帮助您获得最低的总拥有成本(TCO),从而通过提高运营安全性,效率和生产率来节省大量成本。

REXNORD 6990系列混合Mattop链

6990系列混合Mattop链(专利待处理)是为具有高负载或频繁负载变化(人搬运工)的汽车输送机而设计的。链中的钢结构产生了刚度和强度,使链条能够在328英尺(100m)长度(移动的人,车辆或两者组合)的输送机中使用。

Rexnord 3120 Series MatTop Chain

3120系列的Mattop链主要用于工业类型的应用:洗车,打滑处理,人员搬运工,托盘处理和汽车零件处理。坚固的设计以高强度的乙酰材料模制,并利用Rexnord的Twistlock Pin保留系统。

Rexnord 3180 Series MatTop Chain

Rexnord认识到在Skid应用中轻松,经济转化的机会的重要性,并开发了3180系列Mattop链。这些链适用于3.2英寸(81mm)的滑动输送机,可以在转移到下一个输送机之前机械对齐。

Successful processing in tunnel pasteurizers, warmers and coolers requires highly reliable, controlled conveying through the tunnel pasteurizer, and smooth container transfers at the infeed and outfeed. To have the highest conveying chain reliability, to eliminate product waste from tipped or broken containers, and to achieve durable conveying performance, Rexnord’s 2000-series USP MatTop chain and the Rexnord’s 9200 series Fortrex Stainless Steel MatTop Chain are specifically designed for superior performance in the demanding environment of pasteurizers, warmers and coolers.

DTS-C动态内和外饲转移

Rexnord获得专利的DTS-C结合了特殊的转移梳子,并在/外喂链条上到主Rexnord basteurizer带,以进行完全自我清理转移。这消除了死板区域,并确保连续的产品流量消除了后线压力和潜在的产品损坏。

USP超稳定聚丙烯材料

USP材料是稳定剂和抗氧化剂的独特配方,可保护链的聚丙烯材料免受热和/或化学物质的降解。USP材料可提高整个链生命周期的可靠性,并有助于避免停机时间外的风险。

PosiTrack centre guides

获得专利的集成中心引导凸耳可确保最佳的链条跟踪,并防止链侧触摸隧道结构,并消除锁在轴上的链轮的需求。