9300 - the servo inverter family

9300 servo position controller

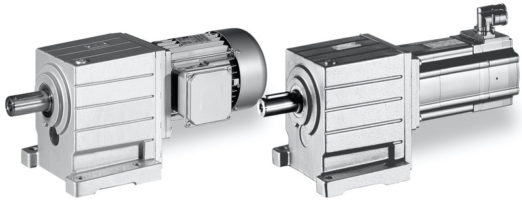

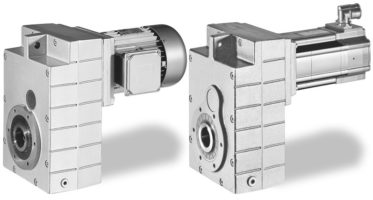

9300 servo inverter

Positioning made easy. A complete position control system

with sequence control is integrated in the 9300 servo position

The basic functions which are most commonly required in a

servo drive are all implemented in the 9300 servo inverter.

controller. An easy commissioning process with only a few

Theelectronicgearboxisaveryimportanttechnologyfunction

values to input is a much more modern solution compared to

in this drive. As an alternative to a mechanical line shaft,

an external positioning control system which uses a more

multiple drives can be run in completely synchronous opera-

complicated programming language. The signals from limit

tion via digital frequency coupling. In the process, adjustable

switches or other drives can also be evaluated at the same

gearbox factors can be used to achieve synchronous ratios

time. If the reaching of the target position is subject to toler-

with a minimum of fuss and a maximum of flexibility. Feed-

ances, then the setpoint position can be automatically correc-

ted by evaluation of a target mark.

backsystemssuchasSinCosencodersareusedasanalternat-

ive to the standard resolver solution to ensure utmost preci-

sion.

ƒ

Flying saw

ƒ

Robotics

ƒ

Palletizer

ƒ

Material feed

ƒ

Conveying and sorting

ƒ

Travelling drives

ƒ

Handling and robotics with distributed intelligence

ƒ

Cross cutter

ƒ

Shaper drives

ƒ

ƒ

Hoist drive

...

ƒ

...

9300 servo register controller

9300 servo cam

Material lengths are processed in many machines. Overprint-

ing, cuts, perforations, embossing and cemented joints need

Mechanical cams are often important components of produc-

tion machinery. Modifying the product or introducing product

to be accurately positioned in accordance with the given print

variants can be a complex process which involves long set-up

image on the material length. However, due to fluctuations

times. Up to eight different curve profiles can be stored in the

caused by the industrial processes (material properties, pro-

9300 servo cam, allowing the machine to switch between

duction parameters), the position of this print image can drift.

these curves without delays during production. Curve profiles

In addition to the basic requirement for an "electric shaft",

can also be expanded/compressed or phase-shifted in online

there is also a demand for a higher-level alignment of the ro-

operation. Several additional functions have been integrated

tational movement on the print image with high register ac-

to allow for the large number of potential applications for the

curacy. The register control which is already integrated in the

servo cam, including for example electronic camshaft control-

drive controller continuously realigns the angular settings of

lers and marker-controlled starting of curves. A function has

feeder rollers, printing cylinders, cutting rollers and other

been integrated especially for the opening and closing of

processing stations with the print image. As a result, over-

welding bars, which achieves a constant welding period with

variable speed.

prints, cuts, perforations, embossing, cemented joints, etc.

are positioned exactly where they are meant to be.

ƒ

Contouring

ƒ

Insetter

ƒ

Welding bar

ƒ

Filling plant

ƒ

Cross cutter

ƒ

印刷单位

ƒ

...

ƒ

...

9300 Servo PLC Technology

9300 Servo PLC

The 9300 Servo PLC Technology has been developed specific-

ally for the general use of technology functions. It is required

The 9300 Servo PLC is bound to impress with its high levels

of flexibility, making it suitable for use in a wide variety of

每当哟u want to use library functions or preconfigured

industry sectors and applications. Pre-configured solutions

solutionsfromthetechnologypackages.Technologypackages

are available for

which can be very easily adapted to your application require-

ments, are available for complex drive tasks. Individual func-

tionextensionscanthenbeprogrammedusingtheIEC 61131-

3 programming languages.

ƒ

Point-to-point positioning drives

ƒ

Cam drives with individual motion profiles

ƒ

Reel changer

ƒ

Winding drives with dancer control or tension control

ƒ

ƒ

Handling and robotics with decentralised intelligence

...

ƒ

Rack drives

ƒ

Complex motion control

ƒ

...

15

†

Servo inverters en 03/2009

9300 servo inverter

Product information